LOGO R&D

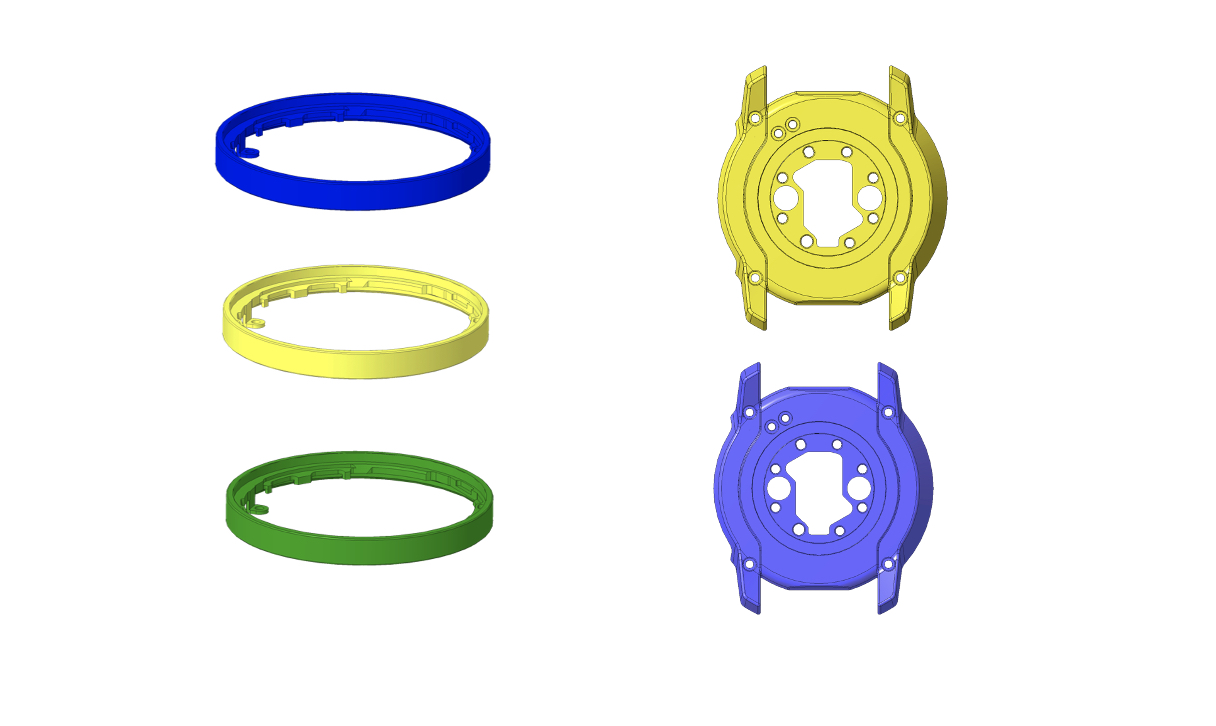

Logo R&D Department is committed to the development and processing of decorative parts and appearance parts of 3C electronic products such as smart phones, tablet computers, notebook computers and smart watches. Through different processing technology and surface treatment technology, different surface effects of products can be met, such as high-gloss mirror, high-gloss anode, anode frosted surface, PVD , printing, etc.

Taking customers and market demand as the direction of efforts, based on higher requirements for appearance effect and product processing accuracy, the department focuses on the development of high-precision plane polishing, 3D robot polishing and surface treatment technology. The materials mainly involved in polishing are titanium alloy, stainless steel, aluminum alloy, ceramics, sapphire and so on. In order to meet the surface processing of different special-shaped parts, combining with the MIMIC system developed by the company, the force value is kept stable in the polishing process, and the traditional dry polishing is replaced by wet polishing to improve the polishing working environment. Processing of new materials And the development of surface treatment technology is the direction we have been exploring.

High precision plane polishing:

Maximum processing size: 10 inches

The thinnest processing thickness: 0.2mm

Total thickness variation (TTV) :≤0.005mm

Gloss (GU): ≥ 1280 GU

Roughness (Ra): ≤8nm

* The above data are measured based on the material SUS 304 1/2H.

3D Robot polishing:

Maximum processing size: 12 inches

The thinnest processing thickness: 0.5mm

Gloss (GU): ≥ 1100 GU

Roughness (Ra): ≤10nm

* The above data are measured based on material AL 6013/6063.

Equipment display

HANG ZHOU AMPHENOL PHOENIX TELECOM PARTS CO.,LTD

Add:No. 98-5 (South), Road 19,

Baiyang Sub-district, Qiantang District,

Hangzhou, Zhejiang 310018

Tel:+86-571-86714425

Fax:+86-571-86714426